blog

How does the boiled wool fabric manufacturers make the boiled wool fabric?

Boiled wool fabric manufacturers’s workshop

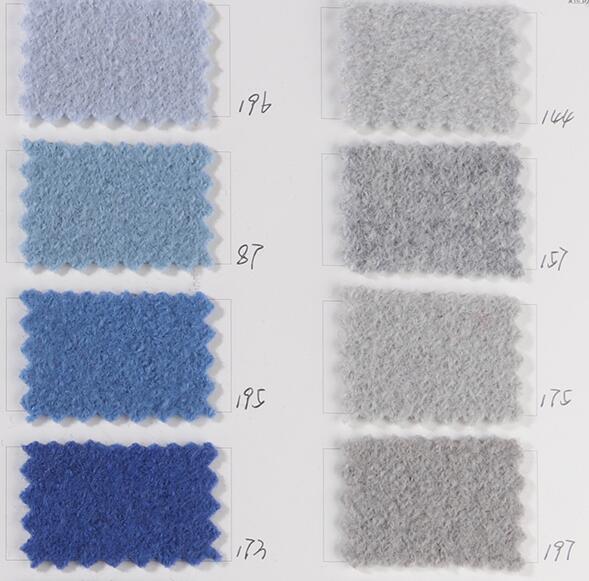

To make the high quality boiled wool fabric, there is 2 dying methods of working process and 5 steps production process. The two dying methods include fiber dye and piece dye. Fiber dye means dying the wool fiber or we called boiled wool material before the yarn spinning. While Piece dye means dying the blank fabric which was already knitted. If the boiled wool fabric manufacturers want to make pink boiled wool fabric, they can dye the wool fiber into pink color before yarn spinning and fabric knitting process. So that the fabric color come out in pink color. Or the boiled wool factory can do another way, they can spin the yarn of undyed fiber, and knit the yarns into the blank fabric, then the boiled wool fabric manufacturer will dye the blank fabric to any color as customers need. If customer need black wool boiled fabric, the boiled wool manufacturers can piece dye the whole fabric into black color as per request. The boiled wool fabric suppliers sometimes do the two dye methods alternatively depend on quality requirements. But for the 100 boiled wool fabric.The boiled wool fabric suppliers noramlly prefer fiber dye for safe quality production consideration. While for the boiled wool viscose fabric, piece dye and fiber dye are both ok for the boiled wool fabric production.

5 Steps of boiled wool fabric production process

Regard the boiled wool knit production, you can see the photos from fiber dye to yarn spinning, then fabric knitting and boiled wool finishing process finally in all.

you can visit the boiled wool fabric manufacturers’ workshop to see and experience the whole fabric boiled process. And to know how the fabric manufacturers create the boiled wool coating fabric from the wool fibers. The boiled wool manufacturers could custom make different quality you need for the boiled wool fabric. If you need to make boiled wool merino fabric quality,high percentage merino wool content then is needed. Sometimes what you need is 100 boiled wool or we called organic boiled wool fabric which similar like italian boiled wool. The 100 boiled wool fabric normally is in light weight. people love the light boiled wool fabric because it feels good when wearing it outside. Anyway UNITEX could do as per your requirements. They could custom make for right quality for you. Now we will introduce you about the boiled wool fabric creating process from Wool fiber dye method.

step 1: Prepare the merino wool fiber material for fiber dyeing. The merino wool fiber need to qualified for the boiled wool fabric quality requirement.

No matter the wool fiber length and finess, all the raw wool top must be inspected and make sure meet the right fabric requirement standard.

After the boiled wool material are prepared ready, the boiled wool manufacturers will put the raw wool top into dyeing machine to dye based of the required colors. The dyeing techlology for the wool top dyeing is complicated and have to careful with the dye material and temprature.

step 2. wool yarn spinning.

after the wool top dyed, then the boiled wool fabric manufacturers will put the dyed wool tops on spinning maching for yarn spinning.

the yarn spec will be followed while the engineer adjust the spinning machine to the right function spec. Different yarn spec will cause different fabric knitting weight. spinning out the right quality yarn is key important to the boiled wool fabric success.

step 3. knitting wool fabric on machine

After the wool yarn was spun, then the boiled wool manufacturers could arrange machine knitting of the blank fabrics with the yarns.The knitting machines has to be adjust in well condition for the boiled wool fabric knitting. Engineer will check carefully the machine condition and do testing knitting to make sure all is well. If the machine not adjusted well, there will be small holes on the fabric, so engineer will do a lot of test to double make sure the machine function well.

Step 4, Boiled the wool fabric in right quality and at correct weight and handfeeling.

After blank fabric are knitted, the boiled wool manufacturer will start prepare the fabric for boiled process. Below photo is a boiled wool machine, the workers will put the dry blank wool fabric into the boiled machine vats.

after the blank fabric are fully put into the boiled vats, the workers will open the water inlet valve to have the water coming in. After the water coming in and reach a standard capacity level, The workers will close the water inlet valve and start the boiling process. You can see the below photo how the water coming in and how the boiled wool process happened.

Wool boiled process is rather difficult and have to be careful as well. The longer time boiled wool process takes, the heavier weight that the fabric will come out to be. The longer time the boiled wool process takes, the shorter of the fabric width will be.So the boiled wool fabric manufacturers will set a certain time span spec for wool boiled time to make sure the boiled wool fabric come out in good condition and of right spec. Below is the photo that the workers measuring the fabric width to check if the wool boiled fabric quality meet the spec or not.

Step 5. boiled wool fabric finishing process.

After the wool boiling process done, the wool boiled fabric manufacturer will do fabric finshing or after treatment such as heat setting,width adjustment and etc.Then the boiled wool fabric manufacture process is completed.If you need learn more about boiled wool fabric info, just contact Unitex.